Our Extrusion Process Stages

THE DESIGN STAGE

The first step in our customization process is to visualize, design and create the required product shape.

The first step in our customization process is to visualize, design and create the required product shape.

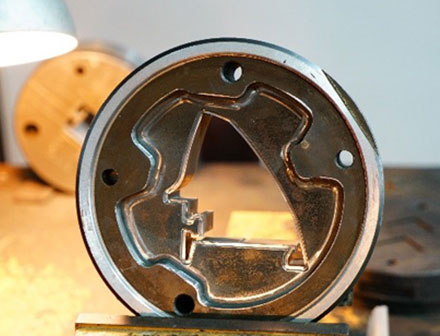

THE DIE CREATION STAGE

The design plan takes shape when the extrusion engineer creates the die to the exact size required.

The design plan takes shape when the extrusion engineer creates the die to the exact size required.

THE EXTRUSION INITIATION STAGE

The extrusion process begins once the die is created and produced and the alloy is decided upon.

Extrusion length up to 12.5m.

The extrusion process begins once the die is created and produced and the alloy is decided upon.

Extrusion length up to 12.5m.

Our Range of Solutions

New Age Aluminium have a complete in house & tool making facilities, the facilities including, Wire Cut Machine, EDM Machine, High Precision CNC Milling and Latch Machine as well as QC Faclities

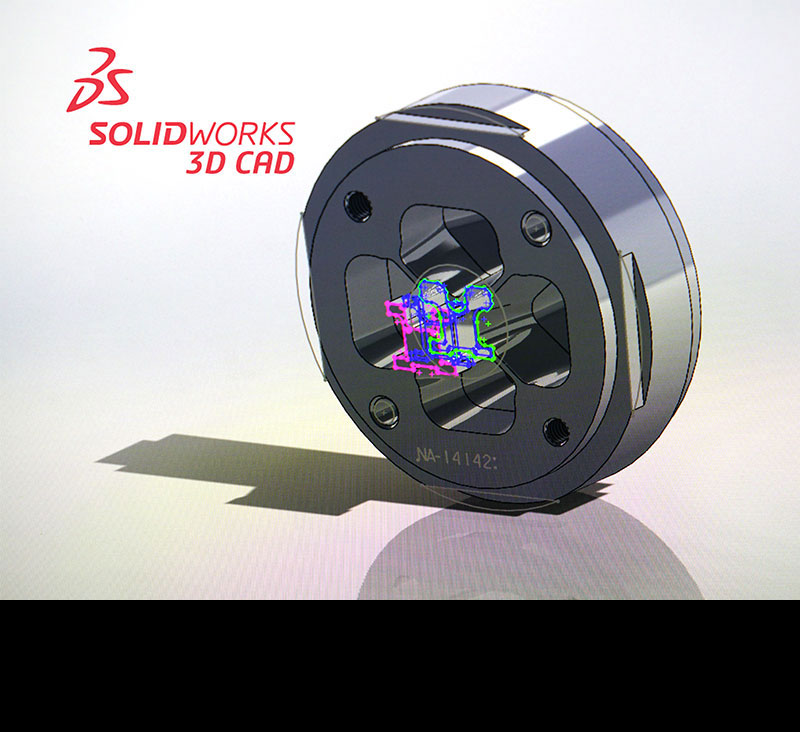

Solidworks 3D Cad

Hot Work Steel

Bandsaw Machine

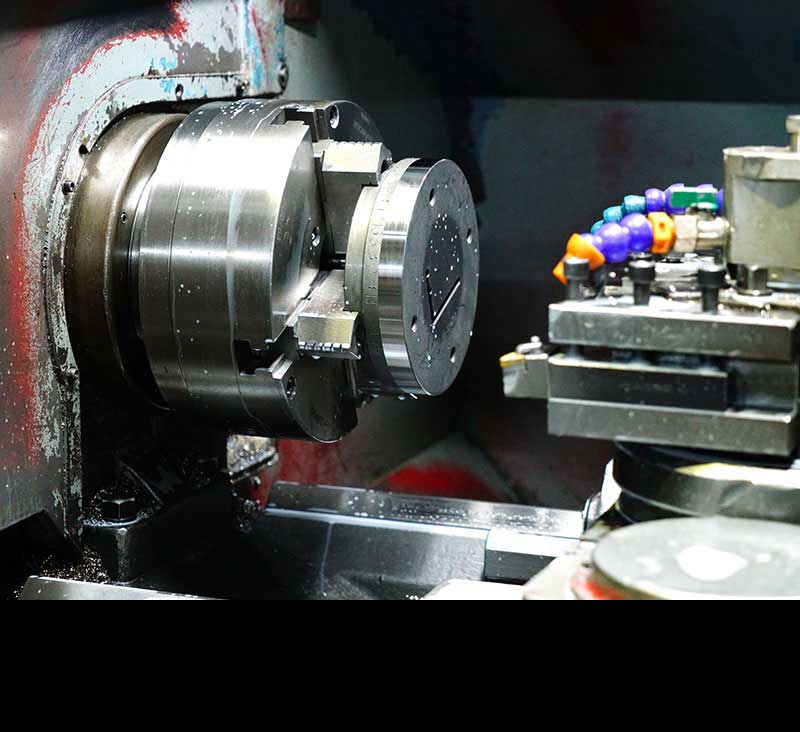

CNC Lathe Machine

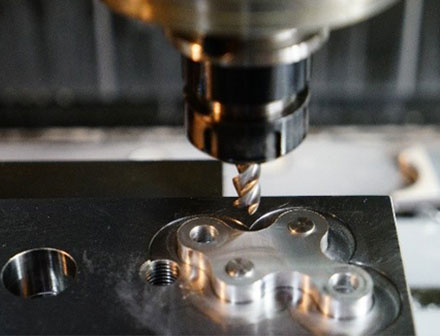

Precision CNC Milling Machine

High Speed Super Drill Machine

Wire Cut Machine

EDM Copper Machining

EDM Machine

Surface Grinding Machine

Die Polishing

QC Check

Better Service

We believe in providing prompt and efficient service on our products and solutions to our customers.

Prototype Samples

We specialize in product design and development and provide solution to our customer by providing wire cut samples and applications prototype. Our customers can have the actual touch-and-feel of the aluminium profiles and applications tests before comfirming the finalized die and tool fabrication.

Improve Existing Applications

We provide flexibility for our customers to modify their existing die designs or improve their existing applications.

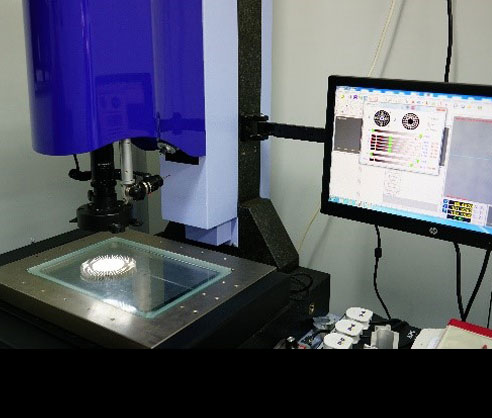

Qualify Control Equipment

We have various Quality Control equipment such as hardness testers, density microscope etc. to ensure which proves we do not compromise on quality for our products.

Microscope Measurement Machine

Height gauge

Caliper Measurement Tool

Hardness Tester

Value Added Services

We are a solutions provider with a ready assembly line to manufacture completed aluminium extrusion products. Our line capabilities comprehensively include:- CNC

- Punch

- Drill

- Deburr

- Bend

- Assembly

We are also well equipped with specialty design equipment to cater for large volume orders as well as close tolerance assemblies. If required to, we can even assemble your products on our manufacturing floor to help simplify your product process flow, therefore saving your time and investments.

ISO 9001 bureau VERITAS certificate

ISO 9001:2015 is an international standard related to quality management, applicable to any organization from all types of business sectors and activities. ISO 9001:2015 provides a framework to respond to changing quality requirements in balance with society, economics and environment.WHAT ARE THE KEY BENEFITS ?

- Ensures your products and services effectively meet your customers' and applicable statutory and regulatory requirements.

- Allows you to measure your progress towards continuous business benchmark improvement and performance.

- Creates of knowledge database for effective exchange of company knowledge.

- Stakeholder and Risk management.

- Seamlessly integrates High Level Structure (HLS) into more than one standard.

- Aligns QMS with core business processes.